In the ever - evolving landscape of mechanical engineering, the Spiral Bevel Right Angle Gearbox has emerged as a crucial component, driving innovation across multiple industries. This specialized gearbox, with its unique design and high - performance capabilities, is revolutionizing the way power is transmitted and machinery operates.

Design and Construction Features

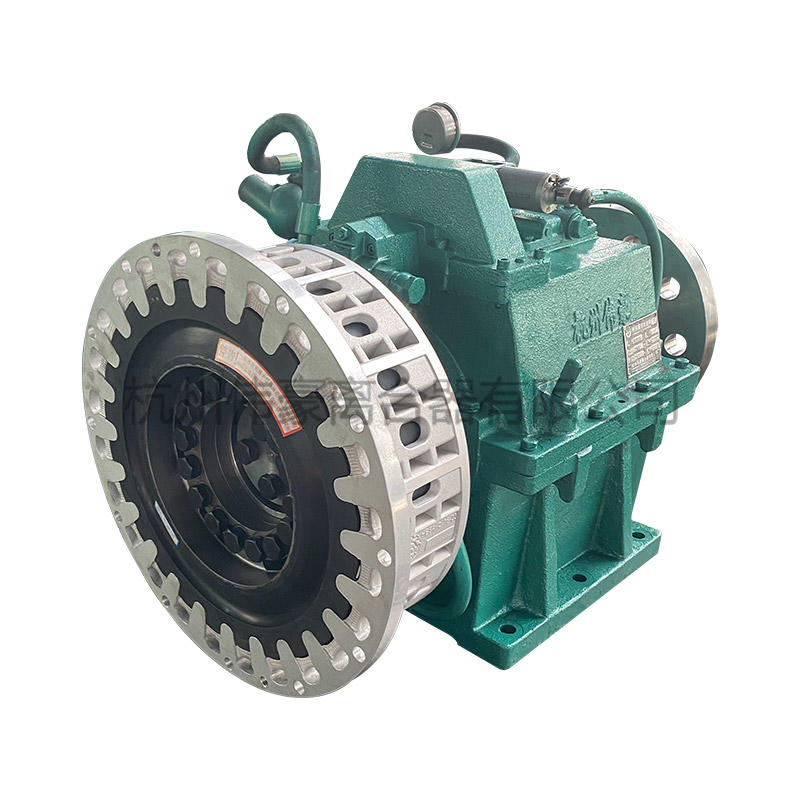

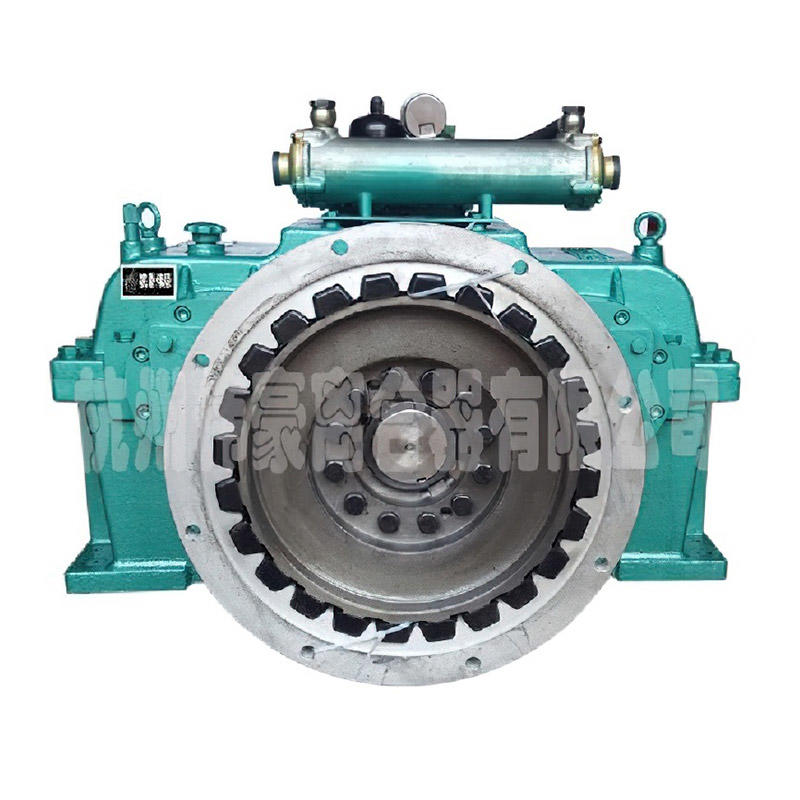

Precision - Engineered Geometry

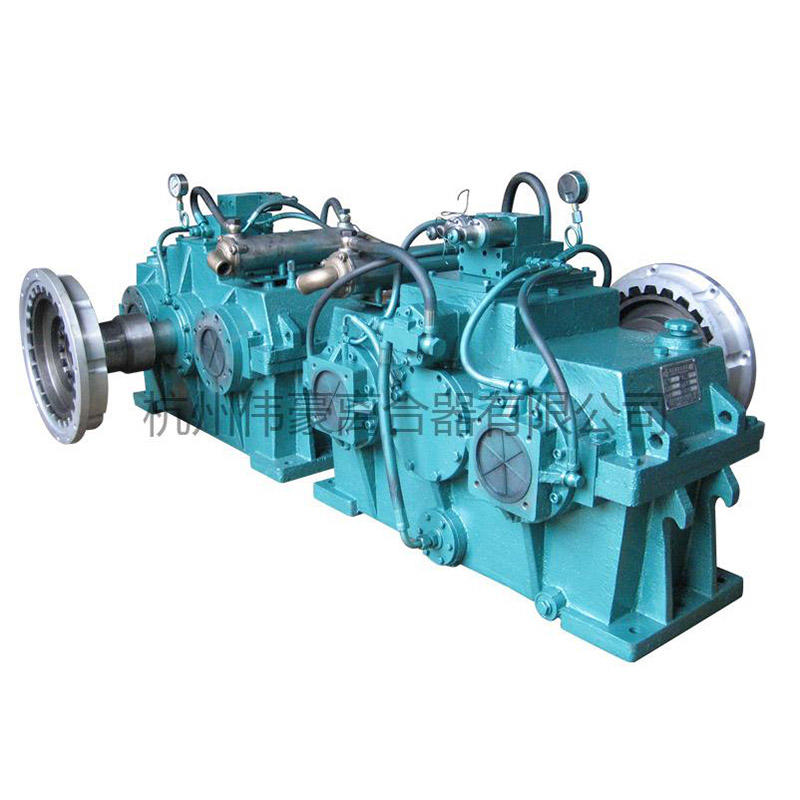

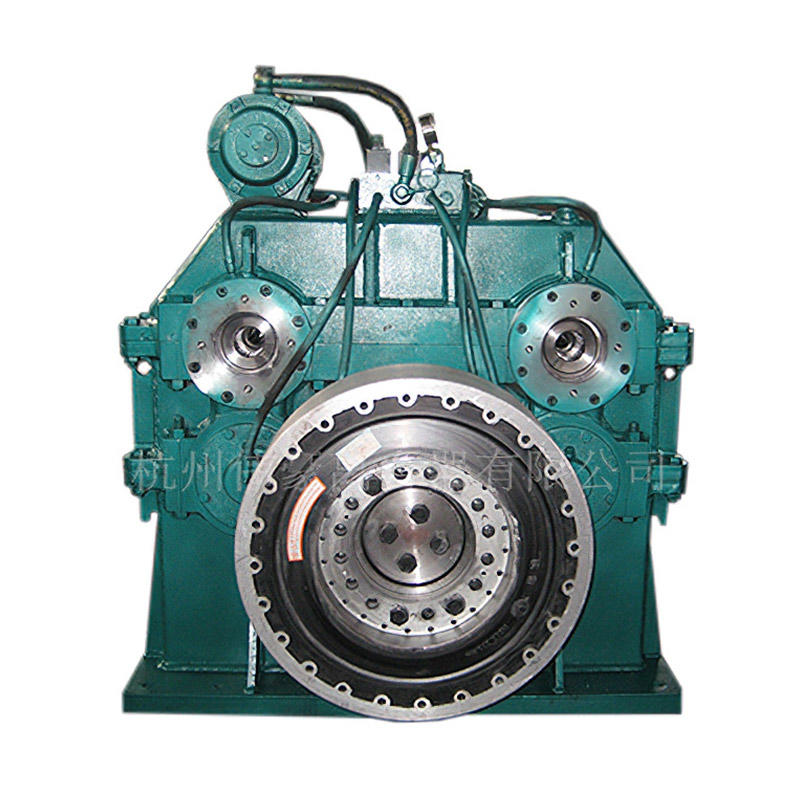

The Spiral Bevel Right Angle Gearbox stands out due to its precisely engineered spiral bevel gears. These gears feature teeth that are cut in a spiral pattern, as opposed to straight - cut teeth. This spiral design allows for a gradual engagement between the gears, resulting in smoother and quieter operation compared to traditional gearbox types. The right - angle configuration enables the gearbox to change the direction of power transmission by 90 degrees, making it an ideal solution for applications where space is limited or specific mechanical layouts are required.

Robust Material Selection

Constructed from high - quality alloy steels, the components of a Spiral Bevel Right Angle Gearbox are built to withstand heavy loads and high - torque applications. The gears undergo heat - treatment processes, such as carburizing and quenching, which enhance their surface hardness while maintaining a tough core. This combination ensures wear resistance, durability, and the ability to operate efficiently even in demanding industrial environments.

Key Performance Advantages

Superior Power Transmission Efficiency

One of the significant advantages of the Spiral Bevel Right Angle Gearbox is its high power transmission efficiency. The smooth engagement of the spiral bevel gears reduces friction and energy losses, allowing for a more efficient transfer of power from the input to the output shaft. This efficiency not only improves the overall performance of the machinery but also contributes to energy savings, making it an environmentally friendly and cost - effective choice for industries.

High - Torque Capacity and Stability

Designed to handle substantial torque loads, these gearboxes provide stable and reliable operation. Whether used in heavy - duty industrial equipment, construction machinery, or automotive applications, the Spiral Bevel Right Angle Gearbox can maintain consistent performance under varying load conditions. The robust design and precise manufacturing tolerances ensure that the gears remain in proper alignment, minimizing the risk of gear tooth breakage and mechanical failures.

Diverse Applications Across Industries

Industrial Machinery

In the industrial sector, Spiral Bevel Right Angle Gearboxes are widely used in conveyor systems, printing presses, and packaging machinery. They enable the efficient transfer of power between different components, ensuring smooth operation and high productivity. In manufacturing plants, these gearboxes play a crucial role in driving motors, pumps, and other essential equipment, contributing to the seamless functioning of the entire production line.

Automotive and Aerospace

In the automotive industry, Spiral Bevel Right Angle Gearboxes are commonly found in rear - wheel - drive and all - wheel - drive vehicles. They are responsible for transmitting power from the engine to the wheels, providing the necessary torque for acceleration and maneuvering. In the aerospace sector, these gearboxes are used in aircraft landing gear systems and various mechanical components, where their high - performance and reliability are essential for flight safety and efficiency.

Future Developments and Trends

As technology continues to advance, the Spiral Bevel Right Angle Gearbox is set to undergo further improvements. Manufacturers are focusing on enhancing its performance through advanced design techniques, such as computer - aided engineering (CAE) and simulation tools. There is also a growing emphasis on developing more compact and lightweight gearbox designs without sacrificing power - handling capabilities. Additionally, the integration of smart sensors and monitoring systems is becoming increasingly common, allowing for real - time performance tracking and predictive maintenance, which will further enhance the reliability and lifespan of these gearboxes.

EN

EN English

English 中文简体

中文简体

View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >>