Advantages of new compressor gearbox technology

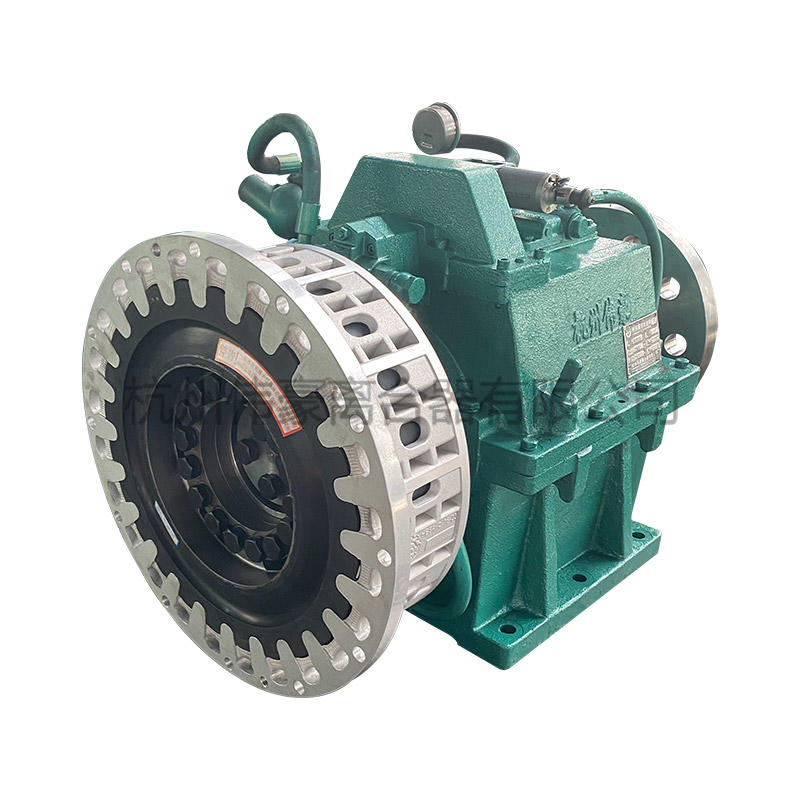

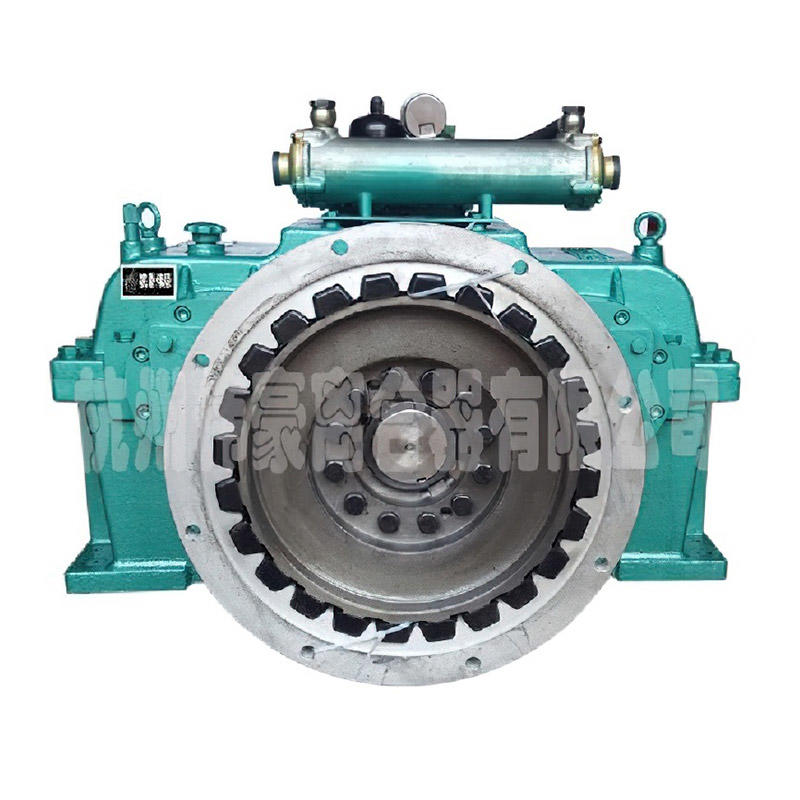

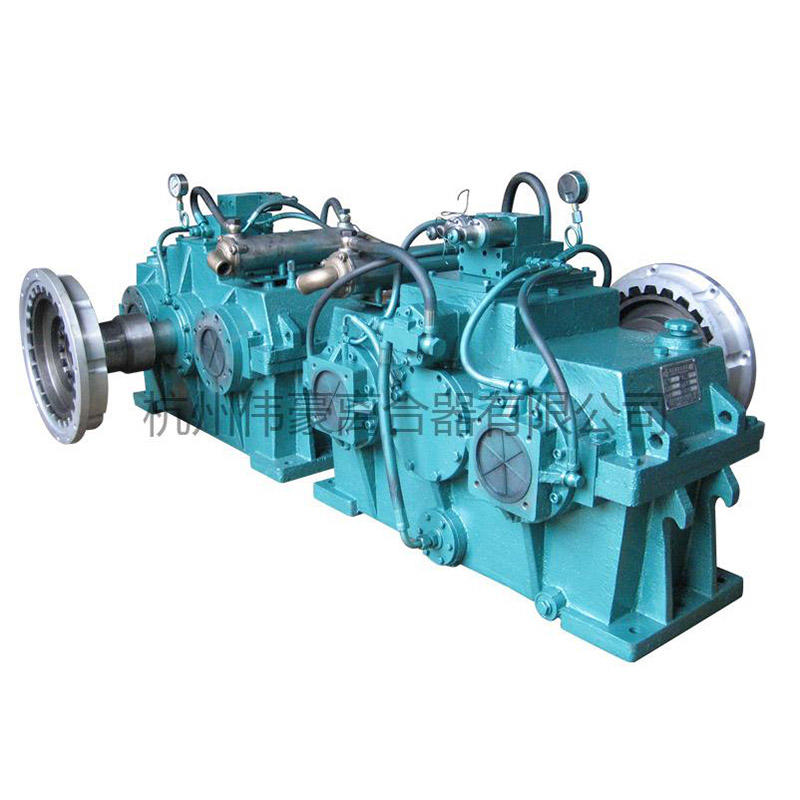

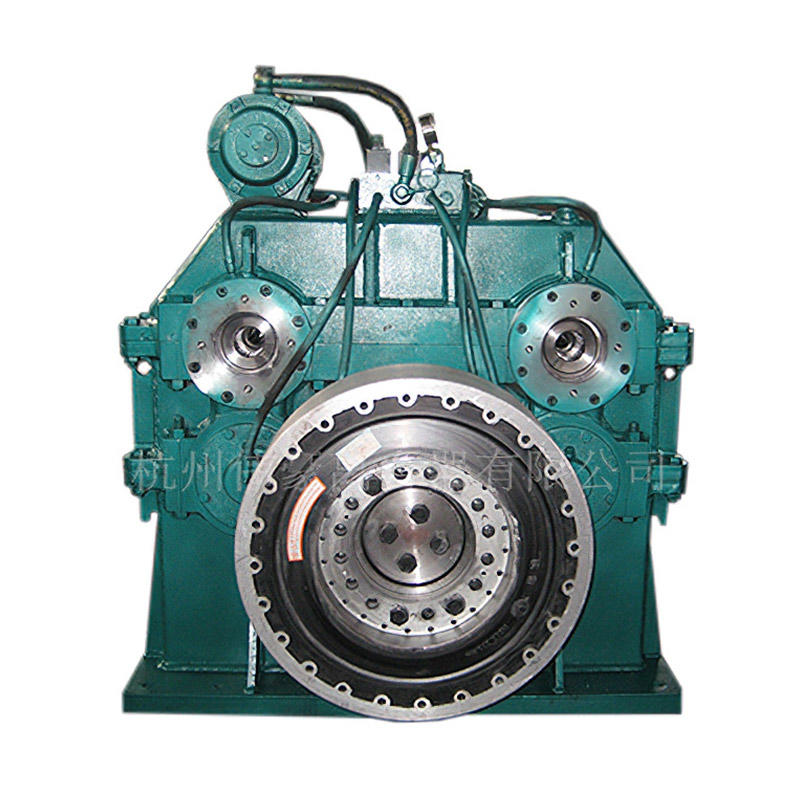

The new compressor gearbox adopts a number of advanced technologies, which significantly improves the working efficiency and stability of the equipment. First, the optimized gear design and efficient gear materials make energy transfer more efficient, reduce energy loss and improve overall transmission efficiency. Compared with traditional gearboxes, new gearboxes can reduce energy waste under the same load, thereby improving equipment operation efficiency. This enhancement allows the compressor to perform the same task with lower energy consumption.

In addition, the new compressor gearbox uses high load bearing materials and design to enhance its stability in high pressure and high load environments. Traditional gear boxes are prone to wear or failure when running for a long time with high loads, while new gear boxes significantly improve the working stability of the compressor and extend the service life of the equipment through strengthening design and wear-resistant materials. This improvement is particularly important for industrial applications that require long-term efficient operation, such as refrigeration and air compressor systems.

Significant advantages of improving energy efficiency

The new compressor gearbox has significant advantages in improving energy efficiency. Compressors often require 24 hours to operate uninterruptedly in industrial production, and traditional gearboxes consume a lot of energy when running for a long time at high loads. Through innovative design, new gearboxes can significantly reduce energy losses, thereby effectively reducing power consumption and helping enterprises reduce operating costs. For large-scale industrial production, especially in energy-intensive industries, improving the energy efficiency of compressors means that companies can complete more production tasks at a lower cost.

In addition, improving energy efficiency not only meets the requirements of modern industry for energy conservation and emission reduction, but also significantly reduces greenhouse gas emissions and promotes the industrial field toward green development. As global attention to sustainable development continues to increase, energy conservation and emission reduction have become the goal of all industries. The emergence of new compressor gearboxes helps enterprises better achieve this goal and promote industrial equipment to develop in a more environmentally friendly and energy-saving direction.

Enhanced equipment stability and reliability

The stability and reliability of equipment are indispensable elements in any industrial application. The technological advances in the new compressor gearbox have greatly improved the stability of the equipment and reduced the frequency of failures. Traditional gear boxes may experience wear, overheating and other problems under high loads and harsh working conditions, while new compressor gear boxes can maintain stable operation under extreme conditions such as high temperature and high pressure through optimized design and material selection.

In addition, reducing friction and heat accumulation is a major feature of the new compressor gearbox. Reducing friction can extend the service life of the gear and avoid equipment failures caused by overheating, thereby reducing repair and replacement costs. Stable performance makes the equipment run more smoothly and reduces downtime caused by equipment failures. For industrial production lines that rely on compressor equipment, this greatly improves production efficiency.

Promote the green development of industrial equipment

As global attention to environmental issues grows, many industrial enterprises are beginning to explore ways to reduce energy consumption and reduce carbon emissions. The emergence of new compressor gearbox technology is exactly in line with this trend. By reducing the energy consumption of the compressor during operation, the compressor gearbox helps reduce energy waste in industrial production and reduce greenhouse gas emissions. Green development has become an important goal in the global industrial field, and the new gearbox technology undoubtedly provides enterprises with more possibilities to achieve this goal.

Improve industry competitiveness and economic benefits

The innovation of the gearbox technology of the new compressor not only helps enterprises achieve energy conservation and emission reduction, but also plays a positive role in improving production efficiency. Improving energy efficiency and reducing failure rates means that companies can reduce production costs and improve the market competitiveness of their products. Especially for large-scale industrial production enterprises, by adopting more efficient and stable compressor systems, enterprises can better meet the market's requirements for product quality and lead time, thereby enhancing industry competitiveness.

EN

EN English

English 中文简体

中文简体

View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >>