Ship transmission technology ushers in a major breakthrough

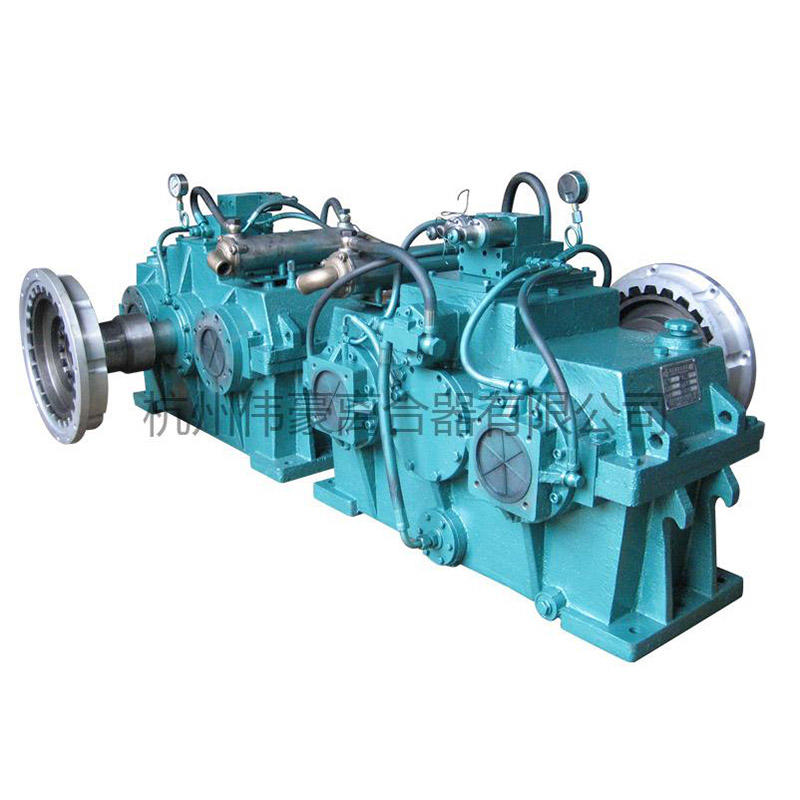

The global shipbuilding industry is undergoing a quiet transmission revolution, and breakthrough progress in the Spiral Bevel Right Angle Gearbox technology is reshaping the performance standards of ship power systems. As a key component connecting the engine and the propulsion system, traditional right-angle gearboxes have long faced reliability challenges under high load conditions. The latest development of the third-generation Spiral Bevel Right Angle Gearbox in 2025 will increase the rated load capacity by 40% and extend its service life by 3 times through innovative teeth design and material processes, providing more reliable power transmission solutions for large cargo ships, engineering ships and naval ships. This technological advance comes as the International Maritime Organization (IMO) implements stricter energy efficiency standards, making efficient and durable drivetrains the core competitiveness of ship design.

Innovation in engineering principles of spiral bevel gear technology

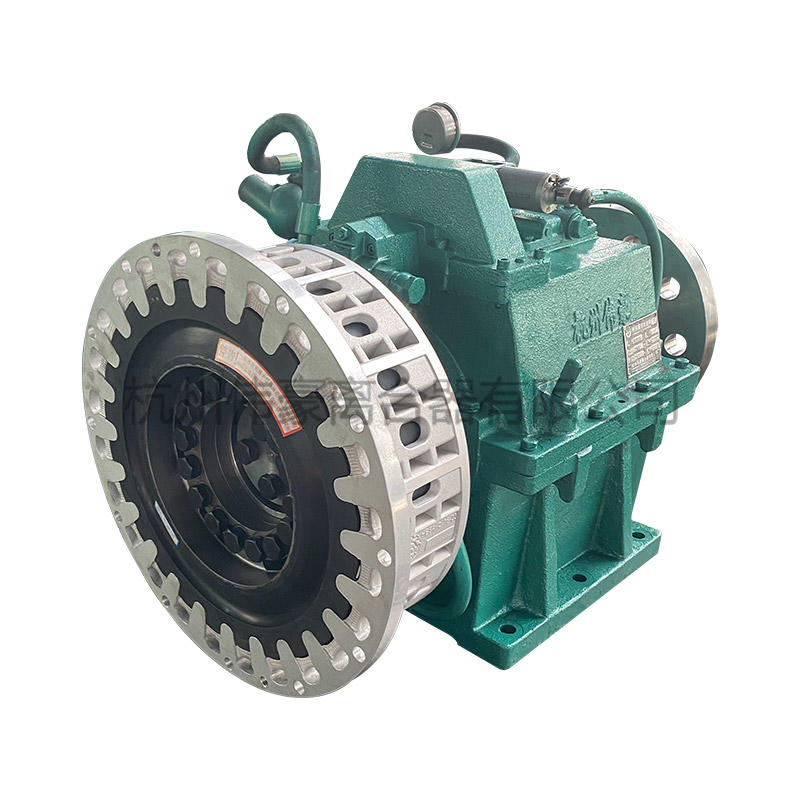

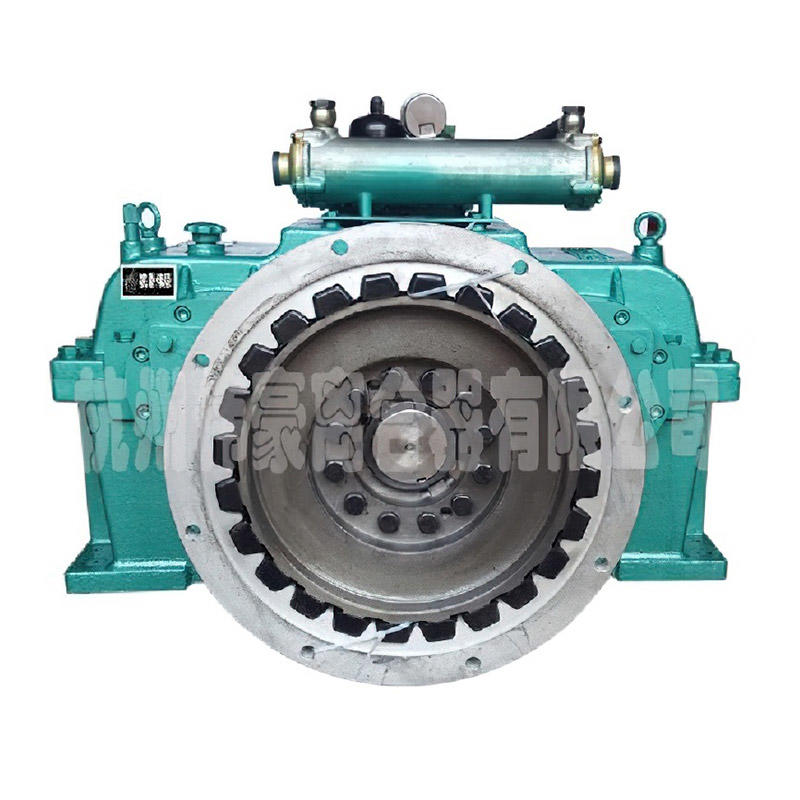

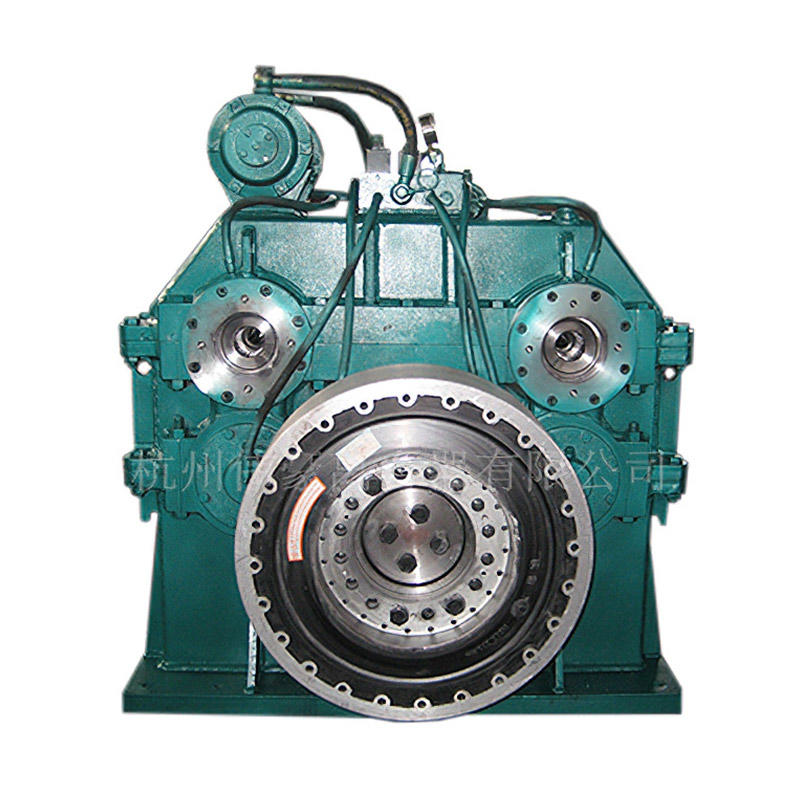

The core breakthrough of the modern Spiral Bevel Right Angle Gearbox is its unique involute spiral bevel design. Compared with traditional spur bevel gears, the progressive meshing characteristics of spiral bevel teeth increase the number of teeth that are contacted simultaneously by 2-3, effectively dispersing the load pressure. Simulation data from a German transmission laboratory shows that the optimized tooth contact stress is reduced by 27%, and the surface fatigue life is increased by 400%. More importantly, the "asymmetric tooth profile" technology developed by Japanese engineers solves the historical problem of excessive gear impact when the ship is reversed by adjusting the curvature radius of the tooth surface, which can ensure that the gears can maintain the optimal contact mode under forward and reverse conditions. These innovations allow the new generation of Spiral Bevel Right Angle Gearbox to maintain a 90° right angle transmission, with a transmission efficiency of up to 98.5% and a 15-dB reduction in noise levels.

Performance verification data in extreme operating conditions

In an accelerated life test that simulates the actual operation of ocean freighters, the new Spiral Bevel Right Angle Gearbox demonstrates amazing durability. Full-load tests for 3000 hours showed that the wear of the gear surface was only one-third of that of traditional products; under extreme conditions of sudden overload of 150%, the gear box can still maintain full functionality, while the comparison group products have peeled off the tooth surface. The certification report of Norwegian Classification Society (DNV) pointed out that the gear pairs that use special alloy steel and plasma nitriding processes have a bending fatigue limit of 2,200MPa, setting a new industry record. The actual ship test is also exciting: the prototype installed on a 180,000-ton bulk carrier, during the Indian Ocean monsoon, reduced the gearbox temperature fluctuations by 40% compared to the older models, and the vibration amplitude is controlled within 0.05mm, fully meeting the strict requirements of the unattended cabin.

Synergistic advances in materials science and manufacturing processes

Spiral Bevel Right Angle Gearbox Behind the performance jump is the dual breakthroughs in materials science and precision manufacturing. The special steel for marine gear developed by American metallurgical experts controls the grain size at ASTM level 10 or above through microalloyation technology, while maintaining the surface hardness of HRC60. What is more revolutionary is the gear blank that is integrated with 3D printing technology. The internal lattice structure has been topologically optimized, and the weight is reduced by 20% while the stiffness remains unchanged. A six-axis linkage grinding machine developed by a Swiss precision machine tool company improves the accuracy of the tooth surface contour to DIN level 3, with a roughness Ra≤0.4μm, ensuring the quality of the oil film formation during meshing. These technological advancements allow the modern Spiral Bevel Right Angle Gearbox to withstand output torque up to 500,000 Nm, enough to meet the main propulsion needs of large container ships.

Key role in improving ship energy efficiency

Against the backdrop of increased pressure on emission reduction in the global shipping industry, the efficient Spiral Bevel Right Angle Gearbox is becoming a key part of improving ship energy efficiency. Calculation shows that for every 1% increase in transmission efficiency, a 10,000-box-class container ship can save about 120 tons of fuel annually and reduce CO₂ emissions by 380 tons. The latest "intelligent lubricating" gearbox has reduced friction losses by another 15% through real-time oil film thickness regulation technology. It is worth noting that this type of efficient transmission system cooperates with LNG dual-fuel engines in particular. Test data from a shipyard in China shows that the overall energy efficiency of the combined system is 8% higher than that of traditional configurations, helping ship owners recover their investment faster. The International Shipping Association predicts that by 2027, the premium of ships equipped with advanced gearboxes in the second-hand ship market will reach 5-8%, highlighting their long-term economic value.

Maintenance strategy and life cycle management innovation

The intelligent upgrade of the modern Spiral Bevel Right Angle Gearbox has completely changed the traditional maintenance model. The built-in vibration, temperature and oil quality sensors can monitor the health status of the gearbox in real time, and the predictive maintenance system has achieved an accuracy of 92%. Operation data from a fleet in Singapore showed that after using status monitoring, the gearbox accidental failure rate dropped by 70%, and the overhaul interval was extended to 64,000 hours. What is more worthy of attention is the application of "digital twin" technology. Through the comparison of virtual models with actual operating data, engineers can accurately evaluate the remaining life and optimize the replacement time. These innovations allow shipowners to reduce the full life cycle cost of gearboxes by more than 25%, greatly improving operational economy.

Prospects of future technological development direction

The next breakthrough point in Spiral Bevel Right Angle Gearbox technology will be the integrated intelligent drivetrain. The prototype products in the laboratory have achieved deep integration with the motor and clutch, and the overall volume is reduced by 30%. The magnetorheological fluid gearbox that German engineers are testing can adjust the transmission ratio in real time through an electric field, which will completely change the fixed speed ratio mode of traditional gearboxes. In the longer term, the maturity of superconducting bearing technology may enable gearbox efficiency to exceed the theoretical limit of 99%. Industry experts agree that with the integration of automation and intelligent technologies, the marine transmission system will usher in the most profound changes since the diesel engine replaced the steam engine in the next five years, and the Spiral Bevel Right Angle Gearbox will continue to play a core role.

EN

EN English

English 中文简体

中文简体

View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >>