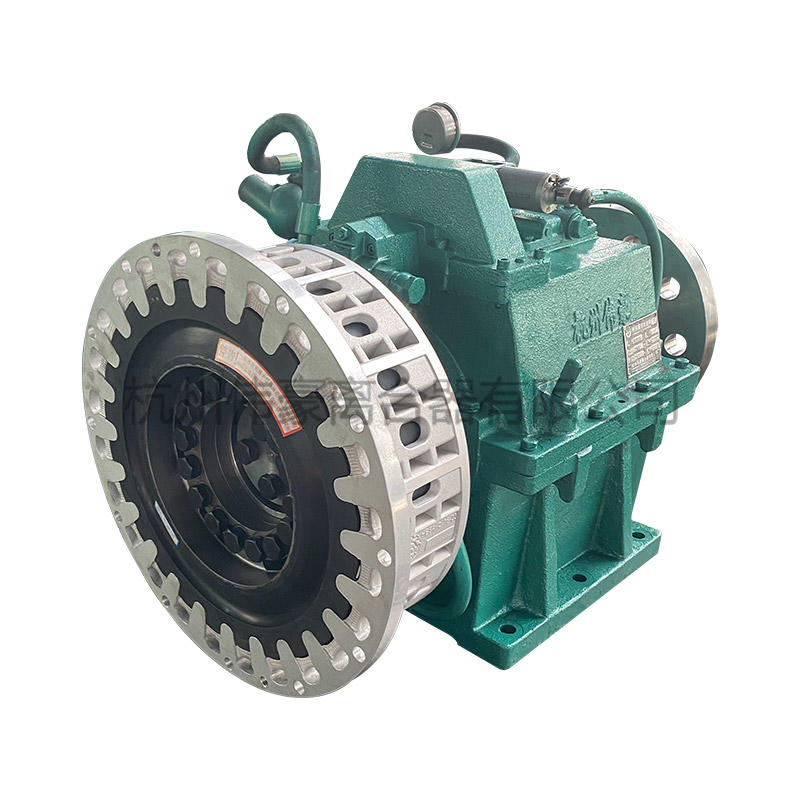

In the automation industry, the transmission system of mechanical equipment plays a vital role. With the refinement of production processes and the continuous pursuit of equipment operation efficiency, Low Speed Gearbox has become an important technical component to improve system reliability, precision and efficiency. Low speed gearboxes have found wide application in various types of automation equipment by converting the rotation of high-speed motors into low-speed, high-torque output. This article will explore the key role of low speed gearboxes in the automation industry and future technology trends.

Basic principles and advantages of low speed gearboxes

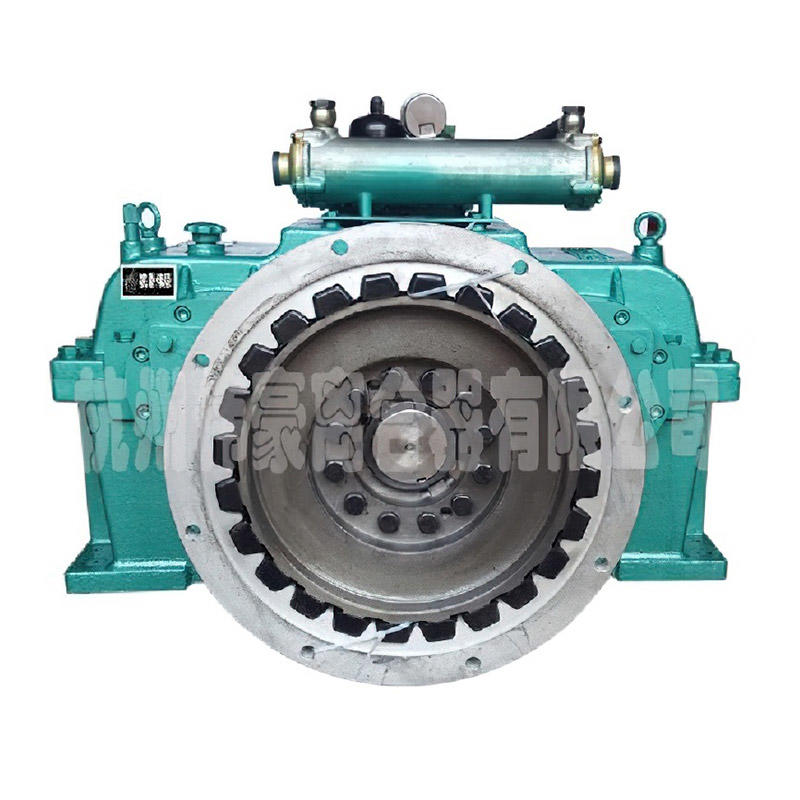

The core function of low speed gearboxes is to reduce the speed of the input shaft and increase the torque of the output shaft through gear transmission. This process enables the high-speed rotation of motors or engines to adapt to application scenarios that require lower speed and high torque. Compared with traditional high-speed gearboxes, the design of low speed gearboxes focuses more on the smooth transmission of torque and lower operating speed, thereby providing more stable and efficient power support for automation equipment.

The main advantages of low-speed gearboxes include:

1. High torque output: Low-speed gearboxes can convert the high speed of the motor into high torque output, which is suitable for applications that require high-power drive, such as heavy machinery, lifting equipment, etc.

2. High-precision transmission: Low-speed gearboxes are usually designed with higher precision to meet the needs of automated production lines for precision control.

3. Reduce equipment load: Through reasonable deceleration and torque adjustment, low-speed gearboxes can reduce the operating load of the equipment and extend the service life of mechanical parts.

4. Energy saving and high efficiency: Low-speed gearboxes can enable motors to work in a more energy-saving way, especially in automated equipment that requires long-term stable operation, which can significantly reduce energy consumption.

Application of low-speed gearboxes in the automation industry

In modern automated production processes, low-speed gearboxes are widely used in many fields and have become a key component to ensure efficient and stable operation of equipment.

1. Industrial robots

In industrial robots, low-speed gearboxes are often used to drive the rotation of the arm or control systems that perform complex tasks. It can accurately adjust the robot's movement speed and torque to ensure that it can efficiently and accurately complete tasks such as assembly, welding, and handling. By adopting high-precision low-speed gearboxes, industrial robots can maintain stable performance when performing precision tasks.

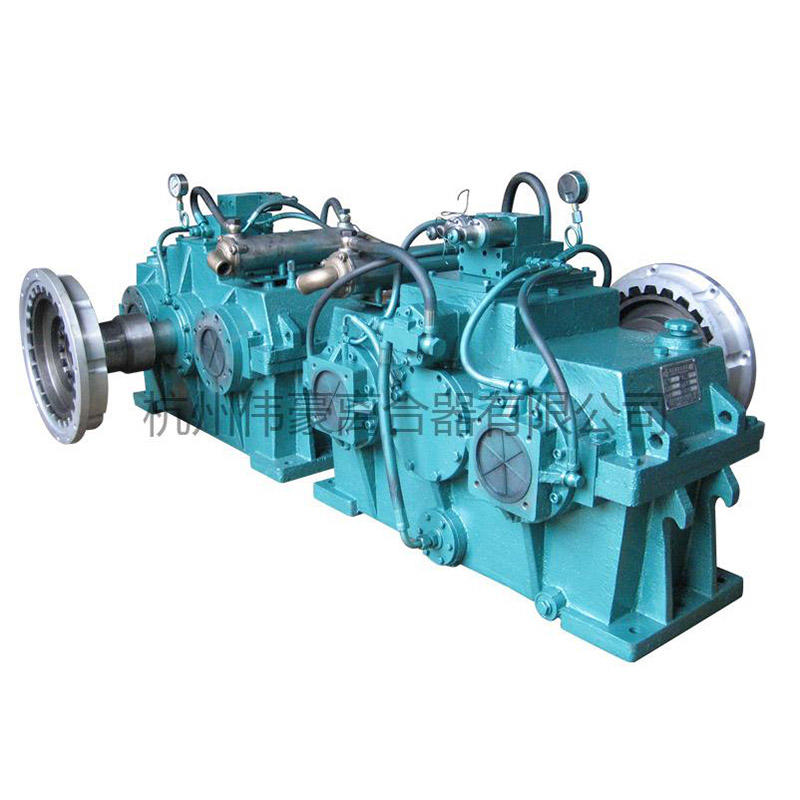

2. Automated conveying system

Conveyor belts are an indispensable part of modern production lines, especially in logistics and manufacturing, where automated conveying systems undertake the task of transporting materials. Low-speed gearboxes ensure that products flow stably and efficiently on the production line by controlling the running speed and load capacity of the conveyor belt. In addition, low-speed gearboxes can also be used to adjust the start and stop and acceleration and deceleration of the conveyor belt, thereby reducing mechanical vibration and loss.

3. Automated warehousing and logistics

In automated warehousing systems, low-speed gearboxes are used to drive equipment such as automated shelves, forklifts and stackers. Since these devices require precise motion control, low-speed gearboxes provide sufficient torque to ensure stable movement of the load, especially in the processing of large-capacity goods. The efficient transmission of low-speed gearboxes can improve the overall operating efficiency of the system.

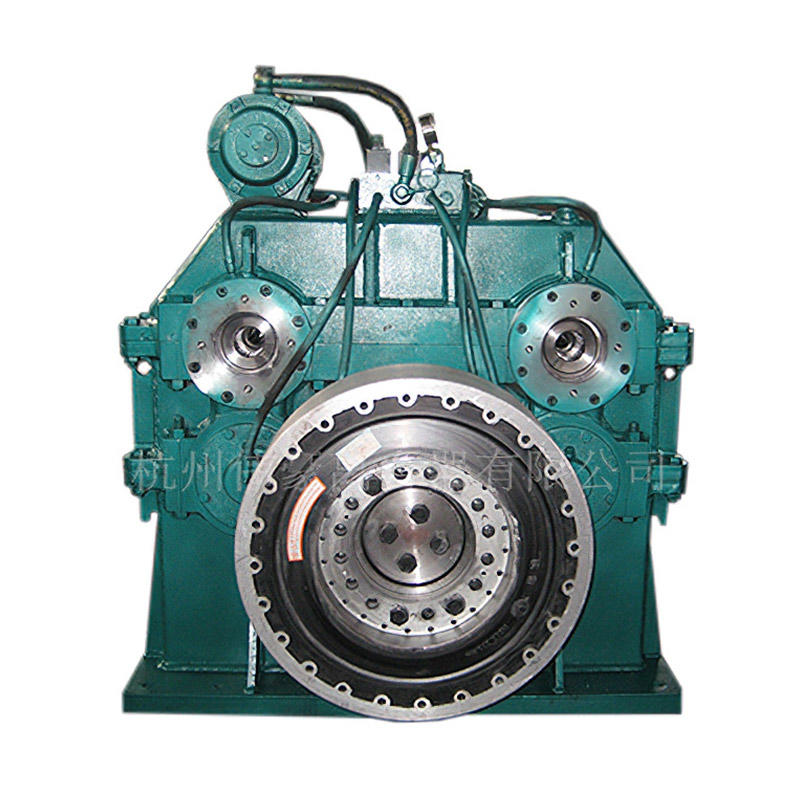

4. Precision machining and automated manufacturing equipment

Precision machining equipment such as CNC machine tools and laser cutting machines often require low speed and high torque to complete complex machining tasks. The precision transmission capability of low-speed gearboxes provides these devices with the required power and stability, ensuring processing quality and efficiency.

5. Lifting and hoisting equipment

In automated lifting equipment and lifting machinery, low-speed gearboxes are used to provide stable torque to lift heavy objects safely and smoothly. Especially in industries such as construction, mining, and shipping, low-speed gearboxes provide the necessary support for these heavy equipment to ensure the reliability of equipment in harsh environments.

Future prospects of low-speed gearboxes

With the continuous development of the automation industry, low-speed gearbox technology is also constantly improving to meet the needs of more efficient, intelligent and environmentally friendly.

1. Intelligent and digital control

The future low-speed gearbox will be more intelligent, and by embedding sensors and digital control systems, it can communicate with other equipment in the automated production line in real time. This intelligent gearbox can warn before overload or failure occurs, thereby avoiding production interruptions and improving the stability and reliability of the system.

2. Higher energy efficiency and environmentally friendly design

With the increasing requirements for energy conservation and emission reduction around the world, low-speed gearboxes will continue to innovate in improving energy efficiency. In the future, low-speed gearboxes will adopt more environmentally friendly materials and designs to further reduce energy consumption, while improving transmission efficiency and reducing carbon emissions.

3. Miniaturization and lightweight design

Automation equipment is increasingly pursuing miniaturization and efficiency, which also puts higher requirements on low-speed gearboxes. In the future, low-speed gearboxes will develop towards a more compact design while maintaining their high torque output capacity to adapt to more compact automation systems.

4. Enhanced versatility

With the diversification of automation equipment functional requirements, low-speed gearboxes will not only be limited to a single transmission task, but may integrate more functions in the future, such as speed regulation, load control, etc., thus providing more options for complex automation applications.

EN

EN English

English 中文简体

中文简体

View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >>