The Ingenious Spiral Bevel Right Angle Gearbox

At the heart of the Spiral Bevel Right Angle Gearbox lies the intricacy of its spiral bevel gears. These gears are meticulously designed with curved teeth, allowing for smooth and precise motion transmission. The spiral bevel configuration ensures optimal contact between the mating gears, minimizing friction, noise, and wear. This precision is crucial in applications where accurate and controlled power redirection is essential, such as in machinery for manufacturing, automation, and robotics.

One of the key advantages of the Spiral Bevel Right Angle Gearbox is its compact and space-efficient design. The right angle configuration allows the gearbox to change the direction of power transmission without the need for additional components like shafts and couplings. This space-saving attribute is particularly valuable in applications where real estate is limited, enabling engineers to design more streamlined and efficient machinery.

The versatility of the Spiral Bevel Right Angle Gearbox makes it a go-to choice in various industries. From conveyor systems in material handling to packaging machinery, the gearbox finds applications where redirecting power at a right angle is essential. Its adaptability extends to industries such as automotive, aerospace, and renewable energy, where precision and efficiency are paramount in complex mechanical systems.

The construction of the Spiral Bevel Right Angle Gearbox emphasizes durability and reliability. The gears are typically made from high-quality materials, and the housing is designed to withstand heavy loads and harsh operating conditions. This robust construction ensures a long operational life, reducing maintenance requirements and contributing to the overall reliability of the machinery in which the gearbox is employed.

Manufacturers of Spiral Bevel Right Angle Gearboxes understand the diverse needs of their customers. As a result, these gearboxes often come with customization options to meet specific application requirements. Engineers can choose gear ratios, input and output configurations, and other parameters to tailor the gearbox to the unique demands of their machinery. This customization capability enhances the adaptability of the gearbox across a wide range of applications.

The spiral bevel gears in the right angle gearbox are designed to achieve high efficiency in power transmission. The continuous contact and optimized tooth geometry minimize energy losses through friction, ensuring that a significant portion of the input power is efficiently transferred to the output. This efficiency is crucial in applications where energy conservation is a priority, contributing to overall system performance.

Recommended Products

-

View More >>

View More >>

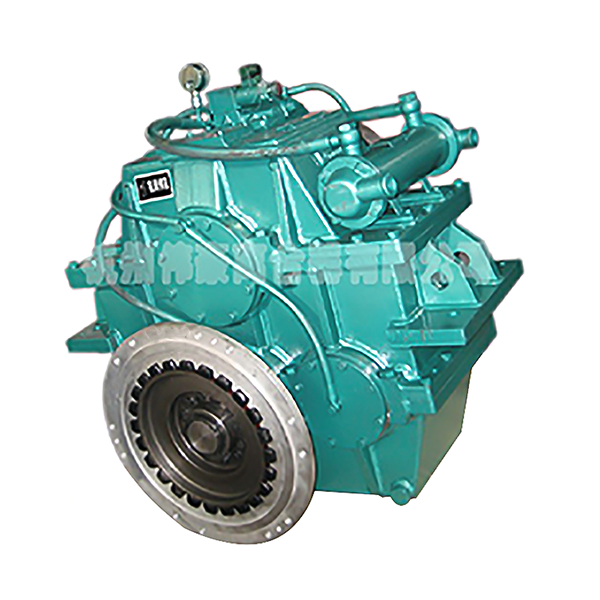

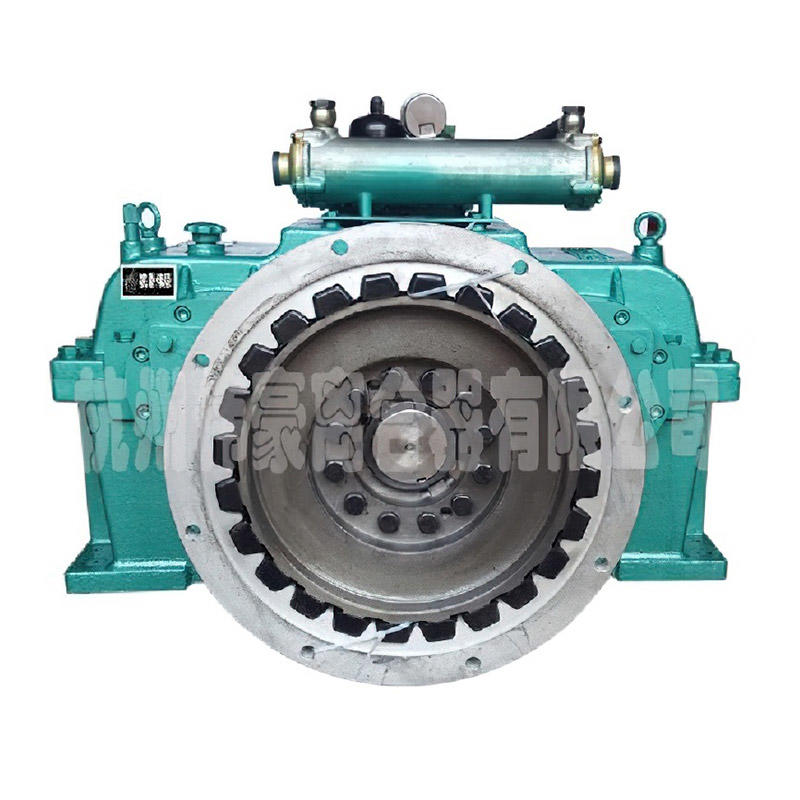

YL250A hydraulic clutch gearbox

Industry: Hydraulic clutch gearbox

-

View More >>

View More >>

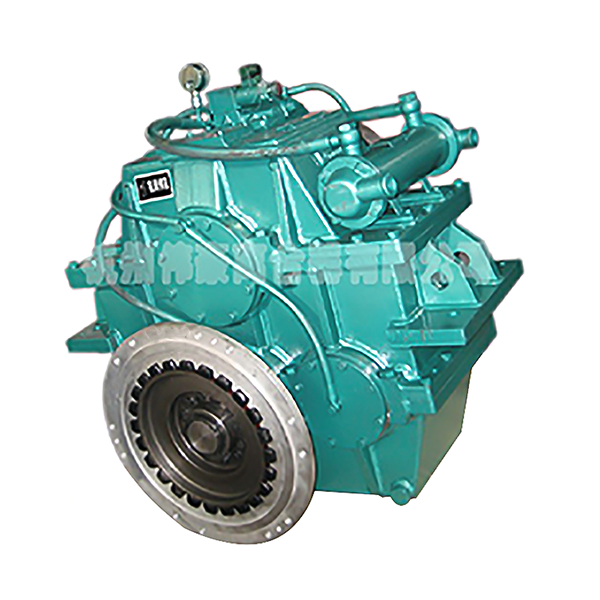

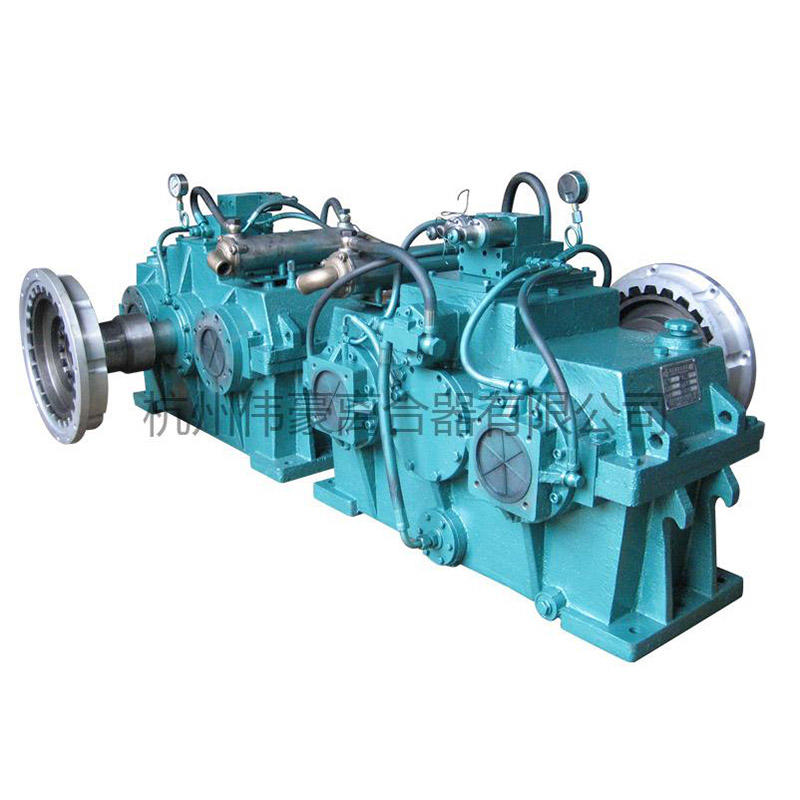

YL320A flat speed hydraulic clutch gearbox

Industry: Hydraulic clutch gearbox

-

View More >>

View More >>

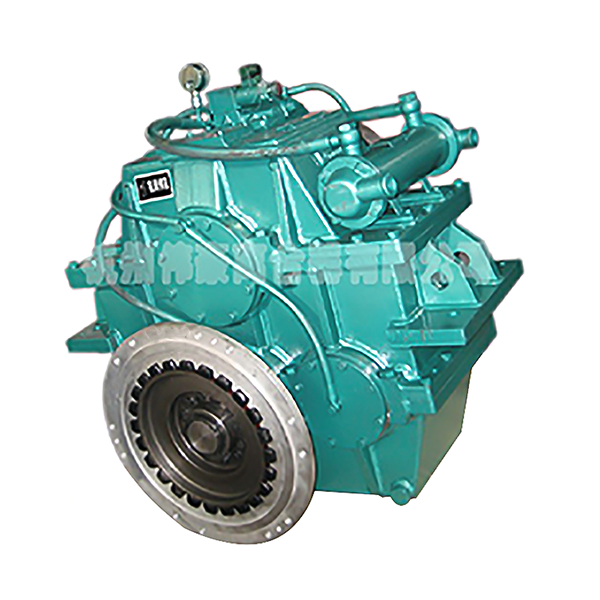

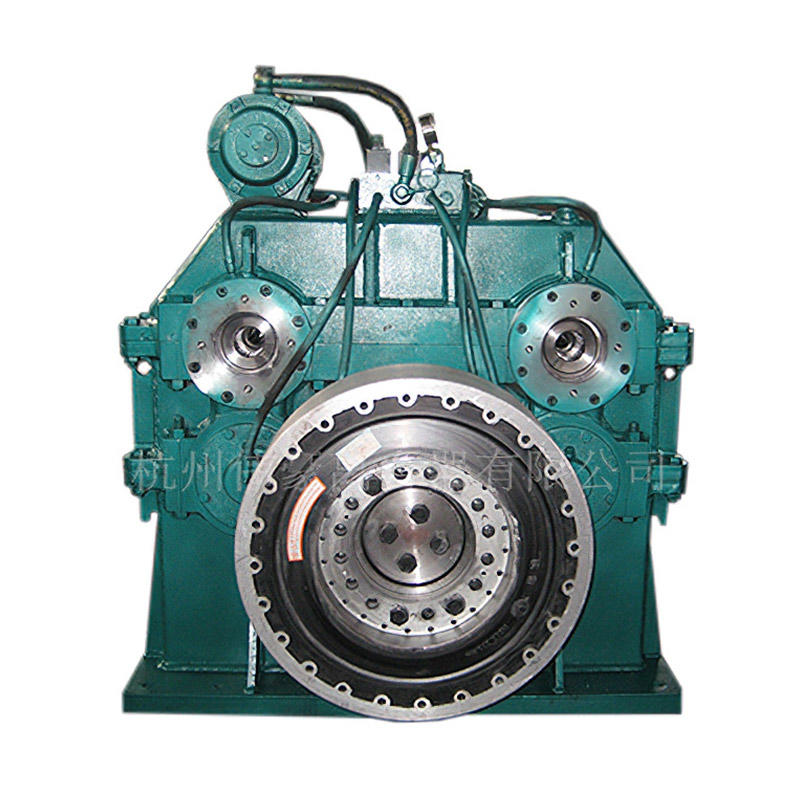

Hydraulic clutch gearbox for YL600A diesel engine

Industry: Hydraulic clutch gearbox

-

View More >>

View More >>

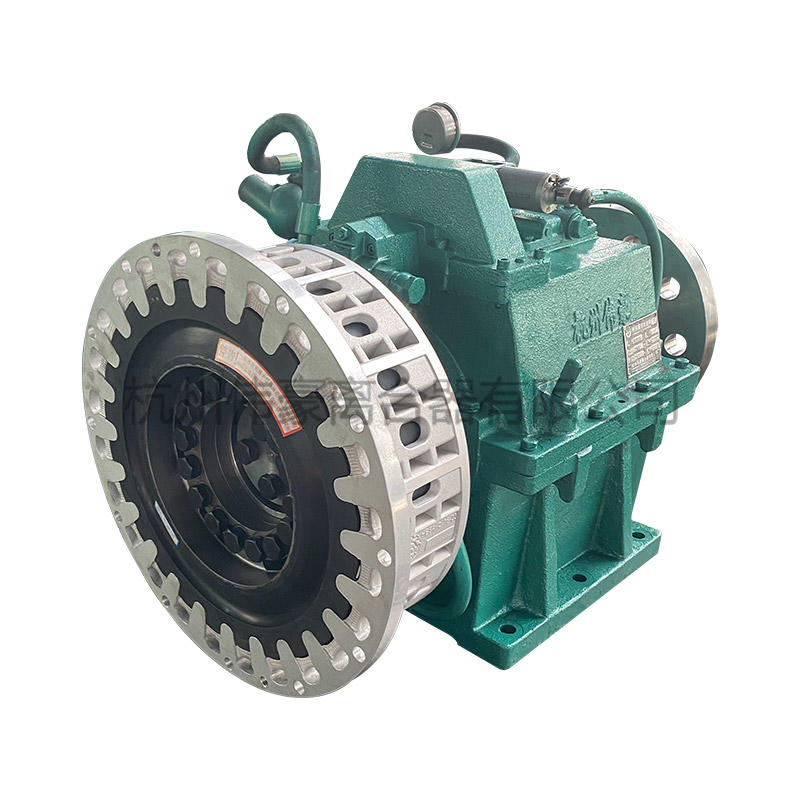

YL800A medium and high-power hydraulic clutch gearbox

Industry: Hydraulic clutch gearbox

-

View More >>

View More >>

Gearbox for YL400 trawler

Industry: Fishing vessel gearbox

-

View More >>

View More >>

YL500 dual output fishing boat gearbox

Industry: Fishing vessel gearbox

-

View More >>

View More >>

YL120 single clutch fishing boat gearbox

Industry: Fishing vessel gearbox

-

View More >>

View More >>

3PL500 Marine Diesel Engine Transmission

Industry: Fishing vessel gearbox

-

View More >>

View More >>

Gear box for YL420 four out trawl fishing boat

Industry: Fishing vessel gearbox

-

View More >>

View More >>

YL520 Single clutch four out fishing boat gearbox

Industry: Fishing vessel gearbox

-

View More >>

View More >>

4WHL500 multi output dual clutch marine gearbox

Industry: Fishing vessel gearbox

-

View More >>

View More >>

6WHL800 medium and high-power fishing boat gearbox

Industry: Fishing vessel gearbox

EN

EN English

English 中文简体

中文简体