Driving Efficiency in Industrial Compression Systems

At the core of the compressor gearbox's functionality is the precise transmission of power from the prime mover to the compressor. This precision is crucial for maintaining the optimal speed and torque required by the compressor to perform its compression duties effectively. The gearbox serves as a bridge between the prime mover and the compressor, ensuring a harmonious match between the power source and the compression system.

Industrial compression systems vary widely in terms of their applications and requirements. Compressor gearboxes are designed to be adaptable to these diverse needs. Whether the compression involves air for pneumatic tools, refrigerants for cooling systems, or gases for industrial processes, the gearbox can be configured to meet the specific speed and torque demands of each application.

Many compression systems, particularly those driven by electric motors, operate within a specific range of rotational speeds. The compressor gearbox incorporates reduction gears to bring down the high rotational speed of the motor to a level suitable for the compressor. Conversely, in certain applications, the gearbox may include step-up gears to increase rotational speed as needed. This flexibility allows for optimal performance across different compression scenarios.

Efficiency is a critical factor in industrial operations, and compressor gearboxes are designed with this in mind. By carefully matching the rotational speeds of the prime mover and the compressor, the gearbox contributes to overall system efficiency. This not only conserves energy but also reduces wear and tear on the components, leading to extended operational life and decreased maintenance requirements.

In industrial settings, where space is often at a premium, compressor gearboxes are engineered to be compact without compromising their structural robustness. High-strength materials, precision engineering, and advanced manufacturing techniques contribute to the construction of gearboxes that can withstand the rigors of industrial environments, including vibrations and temperature variations.

Recommended Products

-

View More >>

View More >>

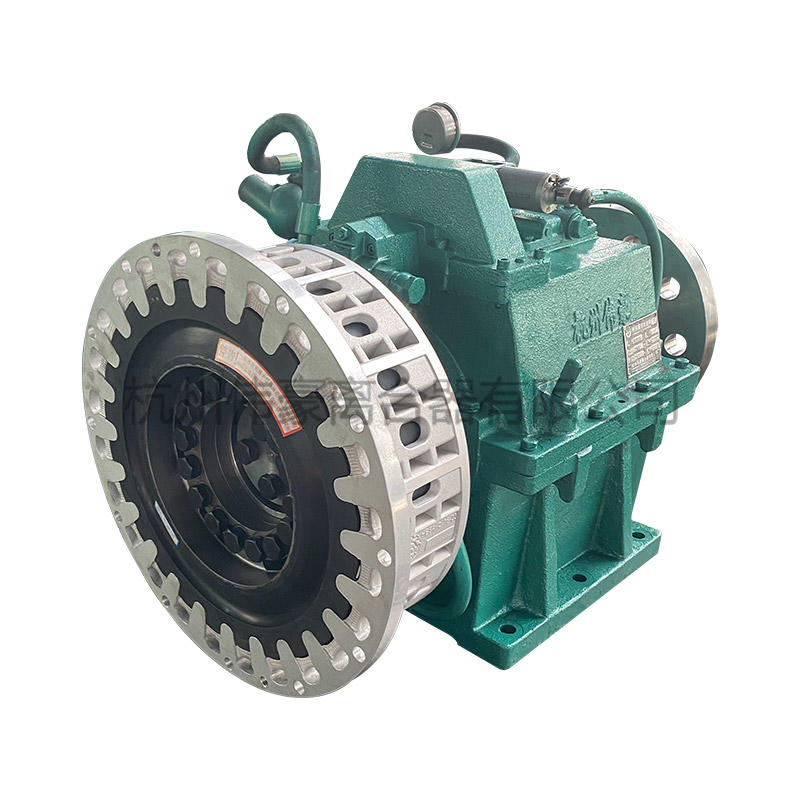

YL250A hydraulic clutch gearbox

Industry: Hydraulic clutch gearbox

-

View More >>

View More >>

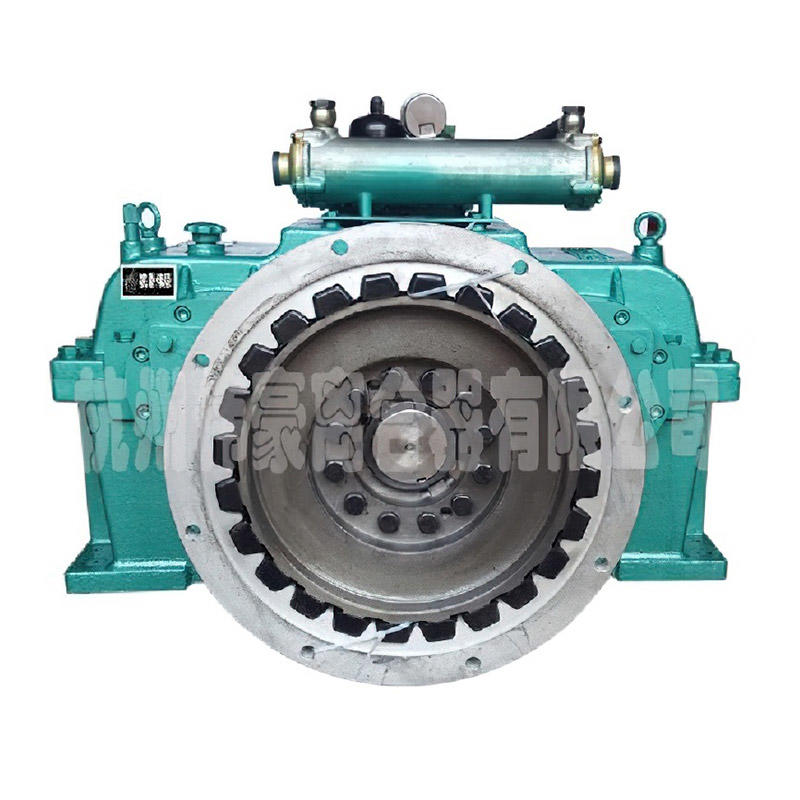

YL320A flat speed hydraulic clutch gearbox

Industry: Hydraulic clutch gearbox

-

View More >>

View More >>

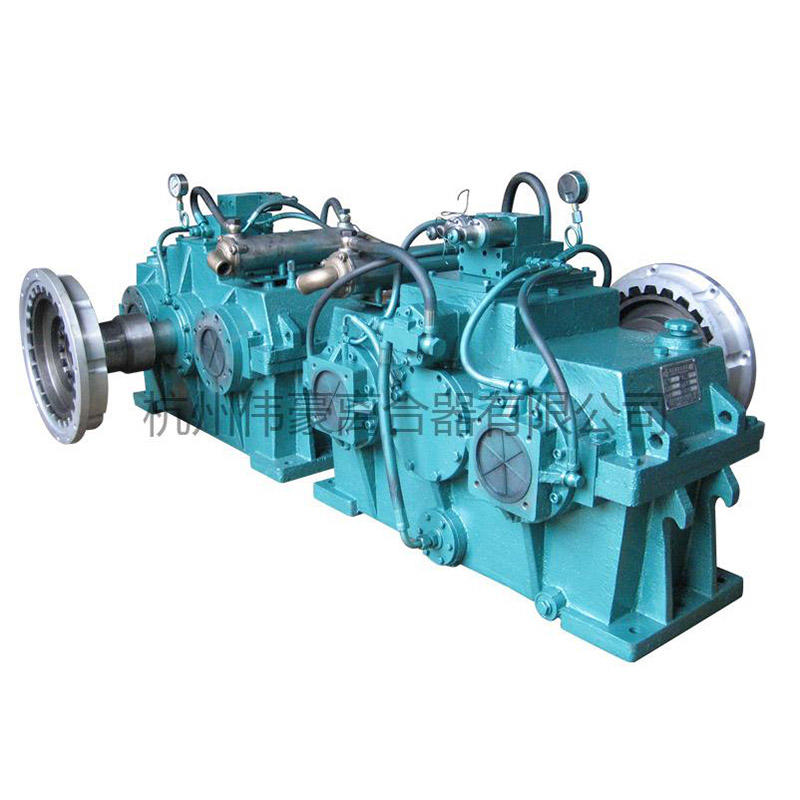

Hydraulic clutch gearbox for YL600A diesel engine

Industry: Hydraulic clutch gearbox

-

View More >>

View More >>

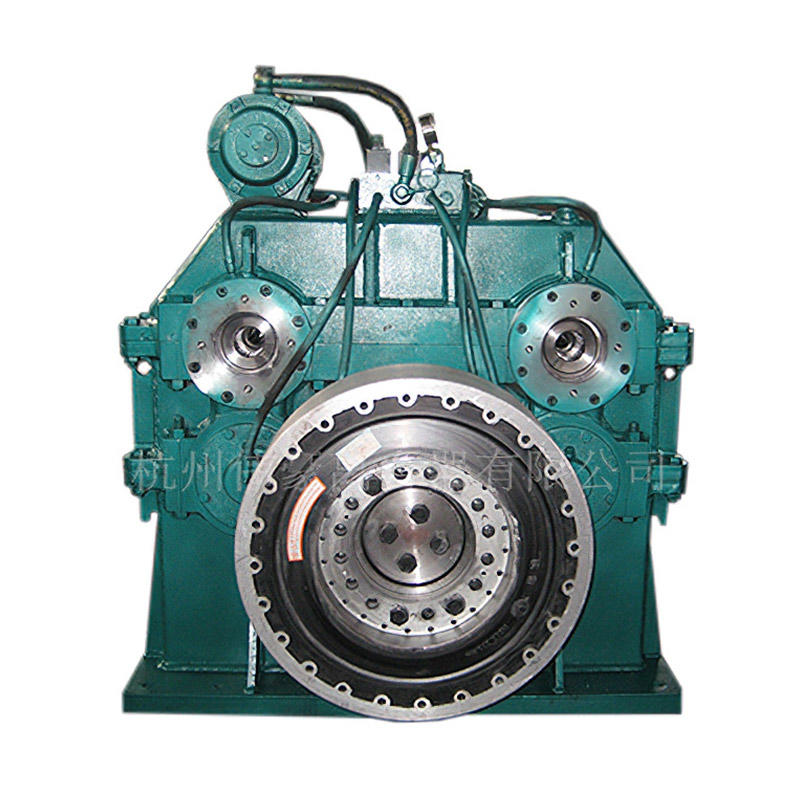

YL800A medium and high-power hydraulic clutch gearbox

Industry: Hydraulic clutch gearbox

-

View More >>

View More >>

Gearbox for YL400 trawler

Industry: Fishing vessel gearbox

-

View More >>

View More >>

YL500 dual output fishing boat gearbox

Industry: Fishing vessel gearbox

-

View More >>

View More >>

YL120 single clutch fishing boat gearbox

Industry: Fishing vessel gearbox

-

View More >>

View More >>

3PL500 Marine Diesel Engine Transmission

Industry: Fishing vessel gearbox

-

View More >>

View More >>

Gear box for YL420 four out trawl fishing boat

Industry: Fishing vessel gearbox

-

View More >>

View More >>

YL520 Single clutch four out fishing boat gearbox

Industry: Fishing vessel gearbox

-

View More >>

View More >>

4WHL500 multi output dual clutch marine gearbox

Industry: Fishing vessel gearbox

-

View More >>

View More >>

6WHL800 medium and high-power fishing boat gearbox

Industry: Fishing vessel gearbox

EN

EN English

English 中文简体

中文简体