Within today's fast-paced society, it is important to stay abreast belonging to the cutting-edge technologies that electricity our machinery and industries. Now brings you the modern knowledge in the arena of multi-pump gearboxes, revealing their inner workings along with the wide range of applications determined by them.

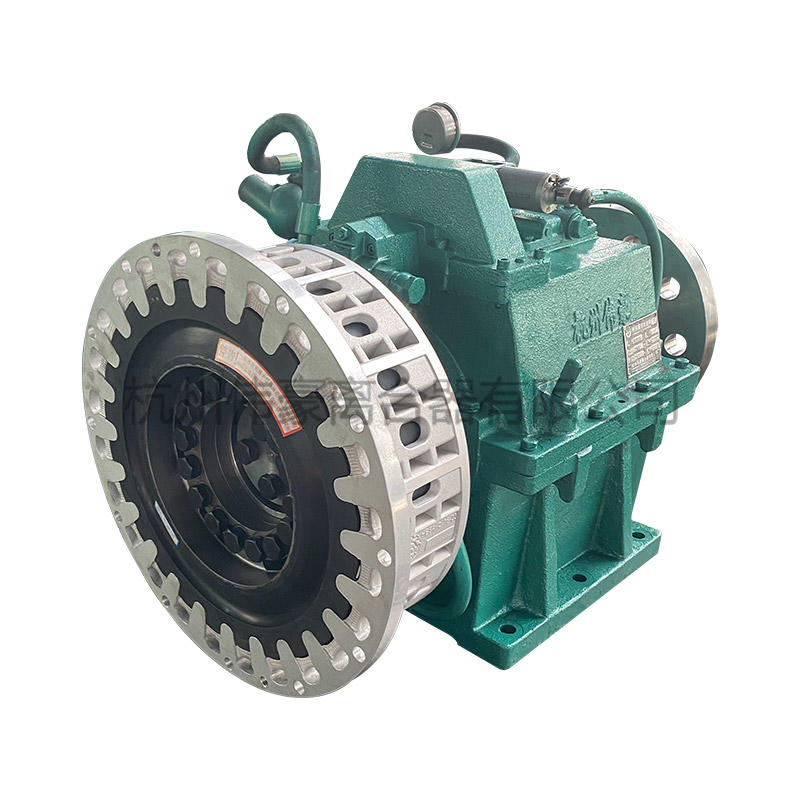

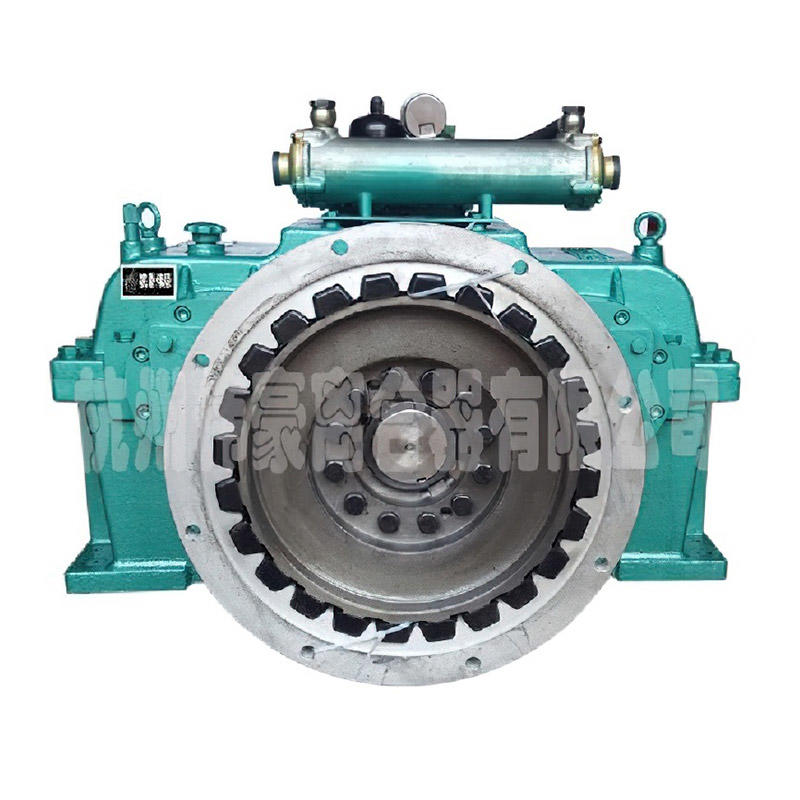

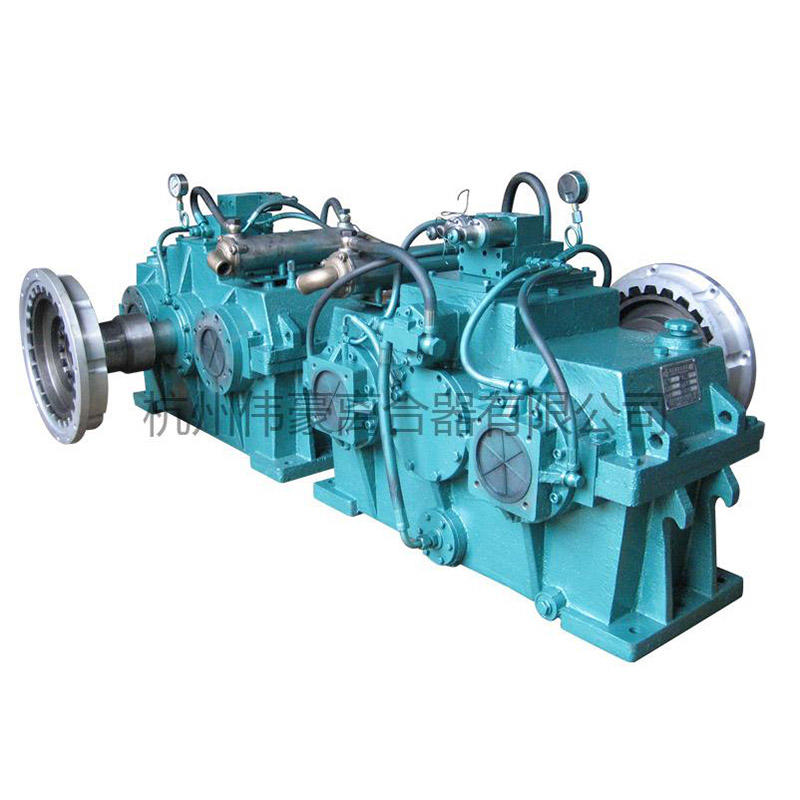

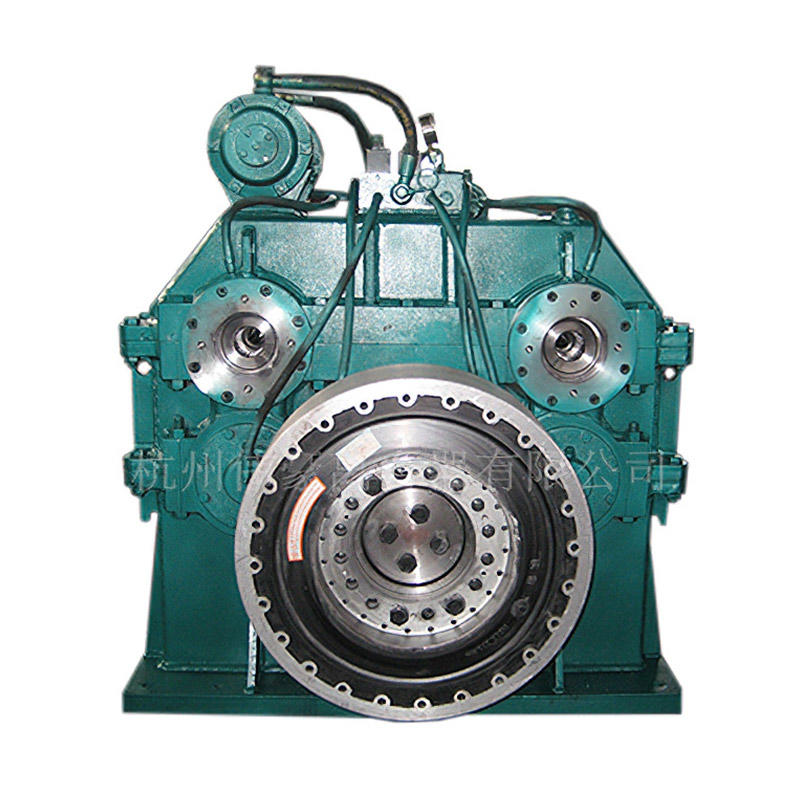

First, an introduction towards inner workings of the actual multi-pump gearbox. Multi-pump gearboxes will be true engineering marvels, designed to optimize power transmission in numerous types of industrial applications. These gearboxes include the power centers of large machinery, ensuring precise handle of fluid flow. The gears and shafts of a multi-pump gearbox are in their heart and require an extremely complex arrangement. These components interact to efficiently transmit electricity from an input source for example an engine or power motor to multiple hydraulic knocks out. Energy loss is minimized in the way, making the gearbox extremely efficient at the job.

The pumps in a multi-pump transmission certainly are a series of hydraulic pushes, each with a unique purpose. These pumps could be gear pumps, vane sends or piston pumps, according to the requirements of the desired application. What makes multi-pump gearboxes special is their ability to work with the pumps in sync, being sure consistent fluid flow whilst maintaining a steady strain and flow. While its bearings and seals are to guarantee smooth operation and durability, the multi-pump gearbox is equipped with high-quality bearings and seals. Bearings lower friction and support shifting parts, while seals avoid fluid leakage, maintaining process integrity.

Now that all of us understand the inner operation, let's explore the many applications that trust in multi-pump gearboxes. In the particular construction industry, multi-pump transmissions is also the driving force behind construction, powering the hydraulic models of excavators, cranes along with bulldozers. They provide the ability needed to lift major loads and perform accurate earthmoving operations. Agriculture: Around agriculture, these transmissions drive the hydraulic systems regarding tractors and various agricultural machinery. This ensures precise control of attachments for example plows, seeders and loaders, ultimately increasing farm productivity. Making: From large presses for you to injection molding machines, multi-pump gearboxes participate in a pivotal role with manufacturing. They maintain regular pressure and flow with industrial processes, helping to raise product quality and efficiency.

Automotive: In the auto industry, multi-pump transmissions would be the unsung heroes of drivetrains, facilitating smooth gear changes along with improving fuel efficiency, particularly in high-performance vehicles.

These applications only scratch the surface from the impact multi-pump gearboxes have got on our daily lives. Their versatility, precision and efficiency generate them indispensable in a group of industries, driving progress as well as innovation.

In conclusion, that fields of engineering and mechanics are constantly changing, and multi-pump transmissions are at the forefront of this progression. Their inner workings as well as applications demonstrate incredible feats with engineering that allow all of us to efficiently accomplish complex tasks. As we move ahead, let us remain curious and anxious about the possibilities presented by these technological marvels when they continue to shape society in extraordinary ways.

Gear box for YL420 four out trawl fishing boat

EN

EN English

English 中文简体

中文简体

View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >>